- Industry insights

- People in tech

- Product development

- Tech trends at BEECODED

- 18 Jul 2025

How Supply Chain Automation Can Save You Hundreds of Labour-Days and Maximize ROI

Ready to save hundreds of labour days and cut your supply chain costs? Read our article now and learn how!

Table of contents

Contributors

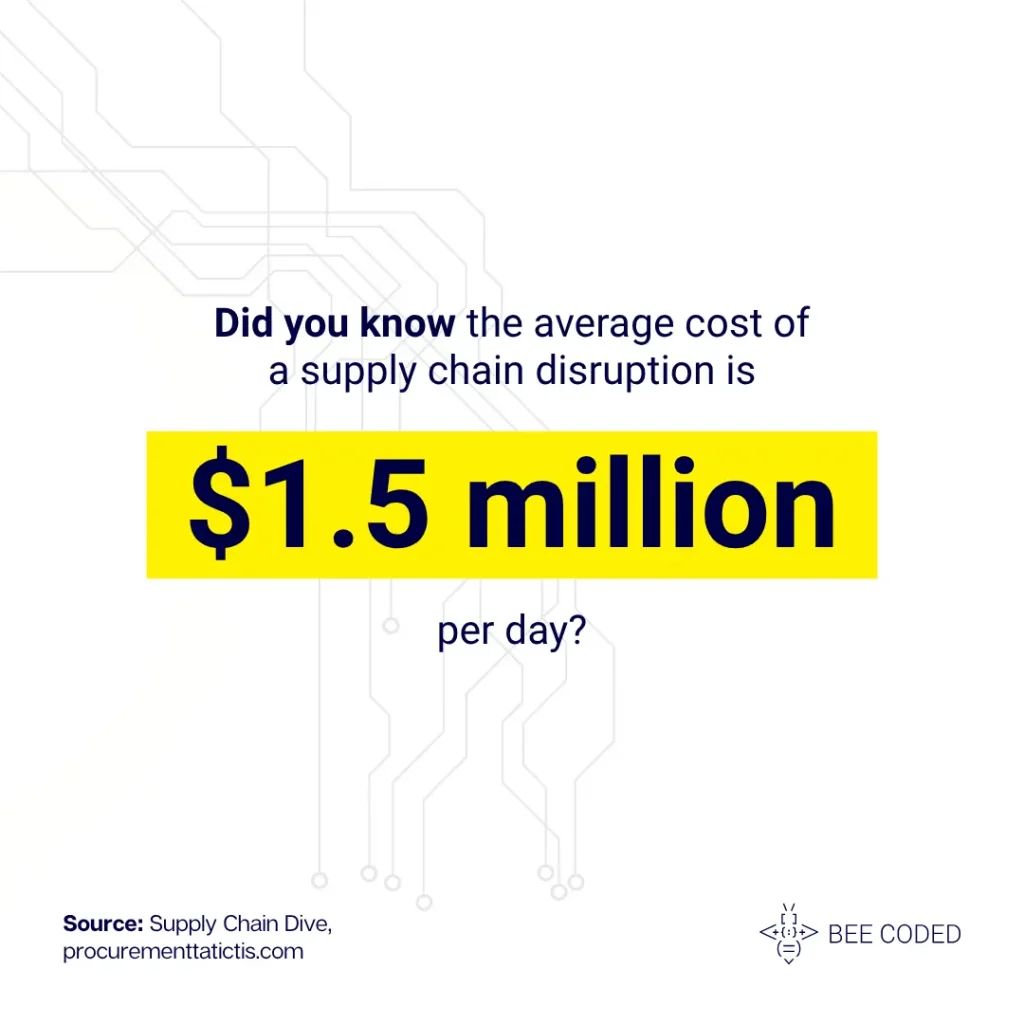

Did you know the average cost of a supply chain disruption is $1.5 million per day? (according to Supply Chain Dive). If an issue drags on for three days, losses can easily exceed $4.5 million. In most cases, these blockages happen because of human errors or delays in data processing. Supply chain automation significantly reduces these risks through

- clear procurement workflow automation,

- accurate demand forecasting automation

- real-time alerts when a supplier has delays, and more.

Keep reading our article to find out how you can save the equivalent of 15 person-days of work every month with supply chain automation.

Understanding Supply Chain Automation

Imagine the journey of a chair: from raw timber in the forest to the factory floor, then the warehouse, onto a truck, and finally into a customer’s dining room. Along this journey, dozens of suppliers, manufacturers, logistics providers and retailers need to be perfectly coordinated. Every step involves: purchase orders, invoices, inventory checks and transportation.

When processes are manual, mistakes happen easily: wrong data entry, no real-time visibility into stock levels, inefficient transportation routes etc. Supply chain automation uses modern technologies to perform repetitive tasks without human input. It uses several technologies, from software and robotics to artificial intelligence. This way, the flow of goods becomes faster, more accurate and far easier to manage.

Supply Data Inconsistencies

What does it mean?

Every supplier sends you data in different formats: Excel, PDFs, emails, sometimes even paper. The same product may show up under various names in your systems (“LED Bulb 10W” vs. “10W White LED”). Plus, prices or quantities may be incorrect due to manual entry.

Problems it causes:

- Wasted time fixing errors instead of growing your business.

- Incorrect invoices leading to overpayments or disputes with suppliers.

- Inaccurate inventory means you risk stockouts or costly overstocks.

The solution:

Procurement workflow automation and supplier data integration standardize all data automatically, directly from your suppliers’ systems. Manual entry disappears and you get a unified, accurate database.

Demand Forecasting Challenges

What does it mean?

Trying to guess how much stock you’ll sell (for example, next month) becomes risky if you rely only on gut feeling or outdated spreadsheets. Without demand forecasting automation, you may overlook key factors like seasonality, promotions or competitor activity.

Problems it causes:

- Stock stuck in the warehouse

- Delayed deliveries because you underestimated demand

- Missed sales opportunities because you didn’t have the right products when customers needed them.

The solution:

Using AI-powered demand forecasting automation tools that analyze sales history and market trends. This way, you optimize stock levels and increase customer satisfaction.

How a Supply Chain Automation Solution Works

There’s no one-size-fits-all approach to supply chain automation. Here are three practical ways companies implement it:

1. Robotic Process Automation (RPA)

Think of RPA bots as digital employees that handle repetitive tasks like data entry, order processing and invoice management. They work 24/7, error-free.

2. Advanced Analytics & Machine Learning for Better Decision Making

Modern supply chains use advanced analytics and machine learning algorithms to spot trends in sales, supplier performance and market demand. This data-driven intelligence helps you fine-tune inventory levels, schedule timely restocks and choose the best logistics partners based on past performance.

3. IoT & Real-Time Tracking

Connected IoT devices — like smart sensors and trackers — continuously gather data on shipments, warehouse temperatures and vehicle locations. This real-time supply chain monitoring means you know exactly where goods are, if conditions are within spec, and if anything unexpected happens.

Key Benefits of Supply Chain Automation

According to aiola.ai, by 2035, 45% of supply chains will be mostly autonomous. Here’s why organizations are embracing supply chain automation:

- Automating manual tasks: workers spend less time on repetitive activities and more time on high-value tasks.

- Minimizing human errors: a supply chain ERP integration dramatically reduces data entry mistakes and mismatched information.

- Improved visibility: you gain real-time insights into inventory levels and shipments.

- Better customer experience: customers receive their products faster and with fewer delivery mistakes.

- Scalability and flexibility: automated systems adapt to demand shifts. For example, during peak seasons like Black Friday or holiday sales, AI-driven fulfillment centers handle higher order volumes without extra hiring.

What Supply Chain Processes Can Be Automated?

It’s true that you can’t fully automate the entire supply chain yet. But even for complex operations, automation delivers massive ROI:

Transportation

- Route optimization automation helps cut delivery times and costs.

- Real-time GPS tracking sends delay alerts instantly.

Warehouse Operations

Automating repetitive tasks frees warehouse staff to focus on supervisory and higher-value work.

Demand Forecasting:

- Predictive analytics makes it easier to plan inventory and pricing dynamically:

- AI models study past sales patterns, seasonal shifts, and current market dynamics to keep inventory levels balanced.

- Smart inventory tools automatically align purchasing decisions with live demand data.

- Real-time analytics enable you to adjust pricing in response to changing supply and demand conditions.

Supply Chain Automation – Success Story with BEE CODED

One of our clients faced a significant challenge: their staff was spending countless hours manually collecting, transforming and reconciling supplier data — a time-consuming process that often caused inconsistencies and delayed reporting. Our BEE CODED team stepped in with a customized supply chain automation solution that streamlined data collection, standardized data transformation and automated reporting workflows.

By eliminating manual bottlenecks, the client now saves an average of 15 person-days of work each month (which translates into 180 days/year) and enjoys more accurate and timely data.

Summary

Yes, supply chain management is one of the most complex fields out there — but complexity doesn’t mean impossible. With supply chain automation, you can save hundreds of labor-days each year, cut costs and strengthen your competitive edge.

Automate today and transform your supply chain into a powerful efficiency engine! Contact us now and let us help you with supply chain automation mastery!

Want to automate other areas too? Check out our articles on HR Workflow Automation and ERP Workflow Automation to unlock even more time savings across your business!

HR Workflow Automation: Cut Onboarding Time by 60% While Ensuring Compliance

How to Reduce Financial Close Time by 3 Days with ERP Workflow Automation

Outsourcing vs. In-house Development: Why Romania is the Best Middle Ground